Comparing Construction Mat Materials, Sizes, and Uses

On demanding job sites, construction mats turn soft, uneven, or wet ground into stable working surfaces for heavy equipment and crews. Choosing the right mat is not just a safety issue; it also affects transport costs, setup time, and how easily you can restore the site when the project ends. Before you order, it helps to compare mat materials, sizes, and typical applications side by side instead of treating all construction mats as interchangeable products.

Comparing Common Construction Mat Materials

Most job sites rely on a mix of mat types over time. The main material families you will encounter are:

Composite mats – Typically made from high-density polyethylene (HDPE) or similar engineered plastics, these mats are strong, relatively lightweight for their size, and resistant to moisture and many chemicals. Surface textures and interlocking edges are molded in, which helps create continuous work surfaces with predictable traction.

Laminated mats – Built from multiple layers of hardwood planks bolted or nailed together, laminated mats offer a balance between strength and weight. They flex slightly under load and are commonly used for access routes and staging where you expect truck traffic and moderate equipment weights.

CLT (cross-laminated timber) mats – CLT mats use engineered wood panels glued in alternating directions, creating stiff panels without gaps between boards. That design helps distribute loads evenly while keeping the weight per mat lower than many options.

Timber and crane mats – Solid timber or thick multi-board crane mats handle the heaviest loads, including large cranes and oversize equipment. These mats are typically much thicker and heavier than laminated or composite alternatives and are common where you need maximum bearing capacity over softer or variable ground.

Which material is right depends on your priorities: reusability, transport efficiency, environmental concerns, or maximum load capacity. For example, composites often shine where lighter handling and repeated deployment matter, while heavy timber and crane mats dominate in the most demanding lifting and foundation applications.

Common Construction Mat Sizes and Load Ranges

Once you understand the materials, the next decision is mat size and thickness. Industry references point out that construction mats are available in many dimensions, but certain sizes show up repeatedly because they balance ground coverage and handling. Typical examples include:

Standard workhorse panels – Many general-purpose construction mats are around 8 feet wide by 14–16 feet long, which provides enough area to support trucks and mid-size equipment while still fitting efficiently on trailers.

Smaller panels (around 4′ x 8′) – Used for lighter equipment, pedestrian access, or tighter spaces where a full-size mat would be excessive. These sizes are common in both wood and composite designs.

Heavy-duty and crane mats – For very large equipment, sizes often step up in both footprint and thickness, with some mats designed specifically for crane outrigger loads and extreme bearing conditions.

Thickness varies by material and application. References focused on wood and composite options note that many standard construction mats fall in the 4–6 inch thickness range, with heavier crane or digging mats getting substantially thicker. Composite mats can sometimes be a bit thinner than equivalent wood mats because engineered materials carry load efficiently at lower thickness.

Regulatory resources on construction best management practices also emphasize that stabilized access surfaces must be sized to support the heaviest expected vehicles and equipment, with enough bearing area to minimize rutting and sediment tracking. That is why many contractors start with equipment loads, subsurface conditions, and allowable deflection when they choose mat sizes.

Matching Construction Mats to Typical Uses

Once you understand materials and sizes, the final step is aligning each construction mat type with its best-fit applications:

Composite mats often see repeated use as temporary access and work platforms on pipeline, utility, and renewable projects where reusability, chemical resistance, and lighter handling matter.

Laminated and CLT mats are common for truck haul routes, lighter crane work, and situations where you need a stiffer surface than basic timber but still want manageable weight and cost.

Timber and crane mats typically support the heaviest equipment—large cranes, bridge work, or high-consequence lifts—where their thickness and mass help spread loads over soft or variable ground.

To see these choices in a project-focused context, this guide on different types of construction mats and where they are appropriate walks through how composite, laminated, CLT, and timber mats line up with specific jobs and environments.

On the regulatory and environmental side, the U.S. Army Corps of Engineers Construction Mat Best Management Practices (BMPs) document explains how mats should be installed, monitored, and removed in sensitive areas such as wetlands, and how they tie into broader erosion and sediment control plans. The U.S. EPA’s National Menu of Best Management Practices for Stormwater Construction likewise highlights stabilized access and surface protection as key elements for reducing sediment tracking and protecting nearby waters.In practice, many contractors combine several mat types on one project: for example, composite mats on recurring access routes, laminated or CLT mats in staging areas, and heavy timber or crane mats under major lifts. The better you understand materials, sizes, and uses, the easier it is to build a mat plan that supports safety, protects the environment, and keeps your schedule on track. Working with an established partner that offers a variety of mat types makes it much easier to choose the right mix for your next job without over- or under-building your ground protection plan.

Composite Mats Prevent Site Incidents and Promote Productivity

When you are planning access roads or work pads on soft, rutted, or environmentally sensitive ground, composite mats are designed to provide site access with minimal disruption. You can also decide whether to rent, lease, or buy those mats, offering options that more closely match your needs.

Guidance on erosion and sediment control emphasizes minimizing disturbed ground, protecting existing vegetation, and keeping access routes predictable so projects stay compliant and safe. Composite mats fit directly into that strategy when they are matched carefully to site conditions and traffic patterns.

Stabilize Access in Challenging Conditions

The first step is understanding where composite mats are most useful. They are often used to create temporary access ways, equipment pads, and staging areas in places where bare ground would otherwise rut, flood, or become unusable after a rain. Mats that are properly sized and connected can support tracked or rubber-tired machines and perform in a variety of ground conditions.

By spreading load across a wider surface area, composite mats help reduce soil compaction, prevent deep ruts, and keep trucks and cranes from sinking or leaning unexpectedly. That stability is essential when you have tight tolerances on crane setup, limited space near utilities, or sensitive terrain that must be protected during construction.

Reduce Common Incident Risks

Many site incidents are tied to basic ground-condition problems: soft spots, unexpected holes, slippery surfaces, or sudden elevation changes. Composite mats help reduce how often those problems show up by creating a more consistent surface and controlling how traffic moves through the site.

Key incident risks that mats can help manage include:

Equipment becoming stuck or unstable in deep ruts or saturated soil

Trip hazards from churned-up ground, loose fill, or uneven grades

Mud tracked into public roads or adjacent properties

Narrow, unpredictable paths that complicate emergency access

Best-practice documents on construction matting describe how stable platforms reduce equipment bog-downs and support safer movement in and out of work areas, especially on remote or environmentally sensitive sites. Agencies that publish matting guidance also emphasize that mats should be part of a documented plan, not a last-minute reaction to a problem.

If you need technical context, resources such as the Construction Mat Best Management Practices document from the U.S. Army Corps of Engineers explain how mats fit into access, protection, and restoration strategies for regulated sites, including wetlands and sensitive soils.

Support Crews While Protecting the Environment

Safety and environmental performance often move together. When the ground stays stable under heavy equipment, it becomes easier to keep erosion and sediment controls working the way they were designed. That may include stabilizing approaches to wet areas, limiting disturbance in buffer zones, and controlling runoff paths during and after storms.

Composite mats support those goals by:

Reducing how much surface you need to cut, fill, or regrade

Limiting sediment tracking from work areas into surrounding ground or public roads

Making it easier to restore the site once mats are removed

Stormwater and erosion control guidance for construction sites repeatedly stresses that access, surface protection, and runoff control should be planned together rather than as separate tasks.

Keep Productivity High Through Better Planning

Preventing incidents is critical, but productivity is the other half of the equation. When the work surface is reliable, you spend less time recovering stuck equipment, patching access, or rescheduling critical lifts. Construction mats support that reliability by giving planners a tool they can size and position around expected traffic flows.

Working with a mat partner offers flexible options and helps you evaluate composite mats alongside other mat types makes it easier to design access. When composite mats are integrated into your overall site-access and ground-protection strategy, they become a practical way to prevent incidents, protect crews, and promote consistent productivity on challenging sites.

Practical Composite Mat Tips for Tough Job Sites

When you are planning access roads or work pads on soft, rutted, or environmentally sensitive ground, composite mats give crews a safer, more stable surface to work from. You can also choose whether to rent, lease, or buy those mats, depending on your project length and how often you expect to need them.

Industry guidance on erosion and sediment control emphasizes minimizing disturbance, protecting existing vegetation, and using stable working surfaces so runoff and rutting stay under control. Resources from the Federal Highway Administration on erosion and sediment control reinforce that access planning is part of that bigger picture, not an afterthought.

Match Composite Mats to Site Conditions

Every job site behaves differently under load. Before focusing on price or rental terms, match your access mats to the actual ground you are working with. On saturated soils, wetlands, or agricultural land, you want mats that spread load effectively and resist sinking so you can reduce rutting and soil compaction. In sloped or poorly drained areas, a stable mat surface also helps control how equipment tracks across the ground and where stormwater flows during construction.

Plan for Loads, Traffic, and Safety

A good mat plan supports safer rigging, better crane setup, and fewer stuck vehicles. That stability can also make it easier to maintain erosion and sediment controls that are required under programs such as the EPA Construction General Permit resources, which stress consistent field practices over the project life. As you refine your mat plan, look closely at the mix of equipment and activity you expect on the site. Key factors to consider include:

Equipment mix – Confirm that mat thickness, material, and connection design can support your heaviest cranes, excavators, and loaded trucks without excessive deflection.

Traffic volume – High cycle haul routes and laydown yards may need more robust mats and tighter connections than low use access spurs.

Traction needs – Surface textures affect how machines behave in mud, standing water, and cold conditions, as well as how safe the walking surface is for crews.

When Renting Composite Mats Makes More Sense Than Buying

Because composite mats are reusable, ownership can look attractive at first glance. With rental and leasing, you still get the performance of composite mats but shift more of the logistics and upkeep to your mat provider. In practice, mat rental or leasing is often the better fit, especially when you are balancing multiple job sites or variable workloads.

Rental or lease options tend to make more sense when:

You need composite mats occasionally or for a single, short-term project.

You want to avoid long-term storage, inspection, cleaning, and repair responsibilities between jobs.

Projects are spread across a wide region, making it more efficient for a provider to handle delivery, placement, and pickup.

You are testing composite mats for the first time and prefer to treat them as a project cost instead of a capital expense.

Factor Logistics and Project Length Into the Decision

Before you commit to renting, leasing, or buying composite mats, think about how your work is structured over the next few years, not just on a single project. For long, multi-phase projects, it may be helpful to keep the same mats on site and shift them as crews move, especially if you can coordinate mat mobilization with other construction activities. On shorter jobs with tight mobilization windows, a turnkey rental that includes delivery and pickup can reduce the number of moving pieces you have to manage.

When you combine that flexibility with a clear understanding of site conditions, traffic patterns, and regulatory obligations, composite mats become a predictable tool for keeping tough job sites both stable and productive.

Do You Need Composite Mats on a Construction Site?

On many projects, access and ground conditions can make or break your schedule. Soft soils, wet weather, and repeated equipment traffic can quickly turn a well-planned site into a rutted mess. That’s where composite mats are often the difference between staying on track and losing days to cleanup and repairs.

When Heavy Equipment Needs Reliable Access

Anytime you’re moving cranes, excavators, or loaded trucks across unprepared ground, you’re dealing with concentrated loads. Without ground protection, those loads can sink into soft soils, create deep ruts, or damage buried utilities. OSHA’s crane standard highlights the need for firm, graded ground conditions that can safely support equipment, often with the help of supporting materials such as mats.

Composite mats spread loads and create a more predictable surface so operators can focus on the work instead of fighting the ground all day.

When Weather Makes Ground Conditions Unpredictable

On paper, a site may look manageable in dry weather. In reality, a few days of rain can turn haul roads and laydown areas into mud. Productivity falls as trucks bog down and recovery equipment is pulled off other tasks. Composite mats are especially helpful when you can’t delay, site access runs through low spots, or tracking mud onto public roads would be a problem.

When You Must Protect Sensitive Surfaces

By planning mats into your access strategy, you can show you took reasonable steps to protect existing conditions and reduce the risk of disputes over restoration. Work in parks, campuses, or built environments often comes with strict restoration requirements. Damage to turf, pavement, or landscaping can lead to extra costs and frustrated stakeholders. Composite mats create a protective layer over:

Finished turf near buildings

Driveways and sidewalks

Landscaped areas around utilities or structures

When Project Specs Call Out Ground Protection

More owners and agencies now call out ground protection or temporary access in their specifications. When you review the documents, look for language on:

Temporary access roads or work platforms

Maximum allowable rut depth or surface disturbance

Restoring surfaces to pre-construction conditions

In these cases, composite mats give you a consistent way to meet requirements instead of improvising with whatever material is on hand. With the growing importance of environmental protection, composite mats have become the most efficient solution.

When Logistics and Reuse Matter

Unlike many temporary solutions that are used once and discarded, composite mats are designed for repeated use across multiple projects. That matters for contractors who work across regions, maintain their own mat inventory, or want predictable access systems they can redeploy.

Because composite mats are lighter than many traditional options, they’re often easier to handle, ship, and store. Over time, that can support better utilization and lower life-cycle cost compared to “single-job” solutions.

You won’t need composite mats on every construction project, but there are clear situations where they should be part of the plan. If you’re dealing with heavy equipment, unpredictable weather, sensitive surfaces, or spec requirements for ground protection, they can help protect the site and keep your schedule moving.

Composite Construction Mats Are Ideal for Environmentally Sensitive Sites

Work in wetlands, floodplains, and riparian buffers comes with tight permit conditions and very little margin for error. A construction mat system lets crews move equipment where it is needed while protecting vegetation, soils, and water quality intact. Modern construction mats spread load across a wider area, limit rutting, and create temporary access that can be fully removed when the job is finished.

How a Construction Mat Protects Sensitive Ground

Sensitive sites usually combine saturated soils, shallow root systems, and limited room for access. A construction mat resting on the surface reduces tire and track pressure, so the subgrade is less likely to deform. Composite panels do not absorb water or break down like timber, which helps them keep a consistent profile across many projects. That stability directly reduces the chance of deep ruts, exposed roots, and bare soil that later erodes into nearby water.

Keeping Wetlands And Buffers Intact

Permits for freshwater wetlands and similar habitats typically prefer temporary measures over permanent fill. Instead of building a raised road, contractors can place a continuous mat surface over existing vegetation and remove it after construction. This approach keeps original contours closer to their pre-project condition and gives plants a better chance to rebound once equipment leaves. A dedicated construction mat inventory also makes it easier to match panel thickness and layout to the level of saturation on each corridor.

For planning access through saturated corridors and crossings, many teams develop a separate matting plan that focuses on wetland edges, streams, and low spots.

Regulatory Expectations You Need To Meet

State and federal agencies often specify construction mats as a preferred method for minimizing disturbance in regulated wetlands. Guidance documents note that mats must be placed over existing vegetation where feasible, kept to the minimum width necessary for equipment access, and removed once work concludes. Regulations may explicitly require heavy equipment in temporarily impacted wetlands to operate on mats to limit soil disruption and protect hydrology. These rules also emphasize cleaning mats between job sites to reduce the spread of invasive species and restoring any disturbed areas so natural conditions can return once work is complete.

Practical Steps For Using Mats On Sensitive Sites

On environmentally sensitive work, a construction mat system should be paired with disciplined field practice:

Identify all poorly drained soils and mapped wetlands during layout.

Keep access corridors as narrow as practical while still safe for equipment.

Place mats from upland or previously matted areas instead of driving directly into undisturbed wetlands.

Stabilize approaches so sediment does not wash onto the mat surface during storms.

Inspect for pumping, uplift, or misalignment and correct issues before heavy traffic continues.

These habits help project teams show inspectors that mats are being used as a true impact-reduction tool rather than a convenience.

Long-Term Value For Sensitive Corridors

Over multiple projects, composite mat systems reduce both environmental risk and lifecycle cost. Contractors face fewer non-compliance findings, smaller restoration scopes, and less conflict with regulators and landowners.

How Composite Mats Reduce Overall Project Costs Over Time

Project budgets are shaped by more than equipment rentals or labor hours. The ground conditions that crews operate on influence towing costs, downtime, remediation bills, and the total time a site remains active. A well-engineered composite mat helps stabilize routes and work pads, which lowers these cumulative costs. Contractors who deploy composite mats consistently see gains in productivity and reductions in repair work, even on complex projects.

Long-Term Savings Through Reusability

Composite mats offer a service life far longer than traditional timber products. Wood can absorb water, warp, or splinter during heavy use. Polymer panels resist these issues and can be reused hundreds of times. Their structure maintains strength across repeated load cycles, which decreases the need for replacement purchases and reduces logistical strain on staging yards. Each return trip to the project extends the value of the original investment.

Lower Remediation Costs After Demobilization

Soil restoration often becomes an overlooked budget item. Deep ruts, stuck equipment, and sediment displacement can turn into costly cleanup. The design of composite mats limits soil disruption and preserves vegetation. They prevent tire cutting, eliminate most ground displacement, and keep contour changes minimal. When the site shuts down, contractors face fewer hours of grading, reseeding, or hauling replacement soils.

For additional planning guidance on how access surfaces influence project stability, project managers often reference off-site discussions such as:

https://www.selectmatblog.com/blog/why-project-managers-prefer-composite-matting-solutions/

Reduced Equipment Wear and Recovery Expenses

Machine recovery costs add up quickly when equipment settles into soft ground. Stable mat surfaces reduce drivetrain stress on trucks and tracked machines. Engines operate more efficiently when they do not have to power through mud or loose soil. Tires last longer, hydraulic systems face fewer strain cycles, and tracked machines avoid unnecessary undercarriage wear. These savings accumulate across every mobilization and demobilization.

Faster Setup and Fewer Weather Delays

Many projects experience downtime after storms or freeze-thaw cycles. Composite mats maintain surface integrity even when underlying soils weaken. This reduces the delays that occur when haul routes become impassable or work pads soften. Crews remain productive while waiting for the ground to dry, and schedules stay closer to forecast. These operational gains help limit overtime, extend equipment life, and reduce personnel idling.

Improved Compliance and Reduced Risk Exposure

Proper surface protection supports environmental compliance and improves site safety. Composite mats help control sediment movement, protect wetland borders, and create stable walking surfaces. Contractors reduce the likelihood of slips, equipment instability, and unsafe working conditions. Lower incident rates directly limit financial loss and administrative time.

Better Material Management and Staging Efficiency

Material storage areas and equipment staging pads often become financial drain points when ground conditions deteriorate. Composite mats create clean, stable surfaces that preserve stored materials and protect against moisture-related damage. They remain level across long deployment periods, which keeps forklifts and carriers moving efficiently.

Top Applications of Composite Mats in Civil and Industrial Projects

Civil and industrial projects operate across varied ground conditions and require surface systems that support safe movement, heavy lifting, and environmental protection. A modern composite mat offers the strength and reliability you need to carry equipment across soft, wet, or unstable terrain. These engineered surfaces maintain predictable performance in settings where soil behavior changes quickly. Contractors often begin project planning by reviewing composite mats for mobility, staging, and protection needs.

Access Roads for Heavy Equipment Movement

Temporary access routes remain one of the strongest use cases for composite systems. The panels span soft corridors, reduce rutting, and create stable lanes for trucks, tracked excavators, and material carriers. They help prevent soil displacement and simplify traffic flow during periods of rain or thaw. Many teams compare mat thickness and tread style when developing routes, using insights from earlier off-site guidance.

Crane Pads and Outrigger Stabilization

Lift operations depend on predictable support beneath outriggers and crawler tracks. Composite pads spread concentrated loads and reduce the risk of machine settlement. Their internal structure resists moisture, heat, and repeated compressive cycles. A well-built mat configuration keeps the working surface level and reduces surface failures during lifts. Composite mats also prevent subgrade pumping when equipment cycles in and out of confined lift zones.

Pipeline and Utility Corridor Construction

Pipeline and utility crews operate across long, narrow corridors where soil composition shifts frequently. Composite mats protect vegetation, maintain a clean work surface, and reduce damage to wetlands and riparian slopes. They create firm platforms for stringing pipe, staging materials, and supporting inspection operations. Because the material does not absorb water, the mats reduce cross-site transfer of sediment or contaminants.

Industrial Facility Access and Maintenance Work

Large industrial sites rely on stable mat systems during shutdowns, inspections, and maintenance cycles. These mats prevent heavy forklifts and transport vehicles from sinking into soft spots. They also protect buried utilities, tank farm surfaces, and paved areas undergoing repairs. Their repeated-use durability makes them suitable for long-term operations that demand reliable ground support.

Environmental Protection and Sensitive Area Access

Many civil projects take place in zones where soil preservation, water quality, and vegetation protection are mandatory. Composite mats reduce compaction, protect root systems, and limit sediment movement along the corridor. Contractors follow guidance similar to USGS soil condition assessments to evaluate ground stability before placing mats. These evaluations help determine where traction surfaces, thicker pads, or extended coverage will preserve the environment.

Material Staging and Equipment Storage Pads

Contractors use mats to establish temporary pads for materials, repair stations, and equipment laydown. Composite surfaces keep storage areas flat, clean, and accessible. They also limit contamination risks by providing a barrier between stored equipment and sensitive ground surfaces. Their tread designs remain consistent through repeated cycles, which improves safety for crews loading and unloading materials.

Composite mats provide dependable support across industrial, civil, and environmental work. A reputable supplier like Select Mat can help determine mat sizing, load ratings, and soil compatibility for each application. With proper planning and inspection, these mats keep crews productive and protect the ground across a wide mix of project conditions.

Composite Mats are the Modern Solution for Heavy Equipment Access

Heavy equipment operators rely on stable surfaces that can support consistent load cycles across difficult soils. A well-engineered composite mat gives crews the confidence to move tracked and wheeled machinery through wet ground, soft corridors, or sensitive project zones. Many contractors now begin access planning with composite mats because they provide predictable performance in nearly every soil condition.

Strength and Support for Demanding Loads

Modern polymer structures distribute weight evenly while resisting rot, moisture, and mechanical fatigue. This is especially important when machines enter areas with silty, sandy, or saturated soils. The design of composite mats helps limit rut formation and prevents equipment from sinking during periods of heavy rainfall. Their traction patterns also give operators better control during turning or reversing.

For teams that need additional guidance on pairing mats with soil behavior, the off site article on matching mat types to ground conditions offers helpful context. See:

https://www.selectmatblog.com/blog/how-to-choose-site-mats-by-soil-type-and-equipment-load/

Key Advantages to Consider

Stable travel paths across sand, clay, peat, or thawing soils

Reusable panels that maintain structure through repeated installation cycles

Improved traction for cranes, trucks, and tracked excavators

Reduced ground disturbance in wetland or regulated project zones

Faster setup compared to timber alternatives

Consistent performance during rain, freeze, and rapid temperature swings

Better Protection for the Environment

A composite mat system shields the ground surface and limits sediment displacement. Because the polymer material does not absorb water, it helps prevent cross site contamination. Crews track less mud onto public roads and reduce damage to vegetation. The surface remains stable even when saturated, which lowers the risk of stuck equipment and emergency recovery work.

Cost Benefits Over Time

While timber options may seem affordable up front, they degrade quickly under repeated load cycles, moisture, and cold weather. Composite mats yield long term savings through durability and lower maintenance needs. They survive hundreds of deployments and reduce the time required for cleanup or restoration. Companies that integrate composite systems into their access plans experience fewer schedule interruptions and reduced remediation expenses. A supplier like Select Mat can help match mat profiles to specific equipment loads and soil types.

Industry Perspective

The Federal Highway Administration notes that unstable ground surfaces contribute to delays, equipment recovery incidents, and increased restoration costs. Stable temporary surfaces reduce those risks and maintain consistent access routes during periods of heavy use. See their guidance on temporary roadway stability and soil protection for more details.

Final Review Before Mobilization

Before operators move equipment across temporary surfaces, inspect the mats for debris, secure interlocks, and verify stable seating. A quick field check prevents surface shifts during the first heavy load cycle. With proper planning, composite mats deliver reliable performance across challenging terrain and keep projects operating efficiently.

You’ll Profit From Cleaning and Storing Construction Mats Properly

Construction mats are built to handle tough jobs, but their lifespan depends on how they’re treated after use. Too many companies overlook cleaning and storage, which leads to unnecessary replacement costs. What if a few simple steps could extend mat life and improve return on investment? Using construction site mats wisely keeps fleets safe, durable, and ready to deploy. Cleaning your site mats may seem like adding an extra step, but proper maintenance is the most direct route to a return on the investment.

Clean Composite Mats After Every Project

Mats pick up soil, chemicals, and invasive plant material. If left unchecked, these contaminants can degrade surfaces and create environmental risk. Power washing or scrubbing after each use keeps mats in top condition and reduces cross-site contamination. For context on why composite mats are easy to clean and sanitize, see our post on load distribution and non-porous surfaces.

Inspect for Damage Before Storage

It’s easy to stack mats and move on. A quick inspection for cracks, warping, and loose connectors catches issues early. Addressing small repairs immediately prevents bigger failures later and avoids downtime when mats are needed again.

Store Mats in Dry, Secure Locations

Moisture and poor storage environments accelerate wear. Stack mats on level surfaces in covered or well-ventilated areas to limit exposure to water, UV, and pests. Organizing by size and connector type makes outbound deployment faster and reduces handling damage. Use dunnage or cribbing to elevate stacks for airflow and to prevent wicking and freeze–thaw damage from ground contact.

Track Mat Maintenance

Simple documentation goes a long way. Log where mats were used, when they were cleaned, and what repairs occurred. Rotating inventory evenly extends service life and helps project managers forecast replacement needs and budgets with fewer surprises. Add asset IDs or QR codes to each mat so crews can scan on issue/return, keeping rotation and maintenance records accurate across teams and sites.

Train Crews on Proper Handling

Even the best mats fail if mishandled. Crews should lift rather than drag and use appropriate rigging for moving and stacking. Good handling practices protect workers and extend mat life. When heavy tracked equipment is in play, interlocking mats distribute loads better and reduce edge damage during turns. The process of mat installation is not difficult, but it must be done correctly.

Quick checklist

Conditions change quickly between demobilization and storage. Use the checklist below at end-of-job and again before the next deployment to confirm cleaning, inspection, and readiness:

Clean mats thoroughly after every project

Inspect for damage before storage

Stack in dry, secure environments

Track usage and repairs in a log

Train crews to handle mats correctly

Proper cleaning and storage may feel like small steps, but they deliver outsized value. By building these practices into your closeout routine, you’ll avoid unnecessary expenses and keep assets ready for the next mobilization. A knowledgeable access mat company will be happy to help you make the best choice.

Cleaning, Inspecting, and Storing Composite Mats to Extend Service Life

Every composite mat is an investment in project safety and ground protection. With proper maintenance, a single mat can serve hundreds of deployments. Without care, even premium panels degrade early due to trapped debris, corrosion at connection points, or improper stacking. Extending service life is a matter of routine cleaning, consistent inspection, and controlled storage.

Why Maintenance Matters

Well-maintained site mats lower replacement costs, reduce project delays, and help contractors meet environmental requirements. Mud, oil, and invasive plant material left on panels can spread contamination from one site to another. Regular cleaning not only preserves the mats but also protects your company from compliance penalties.

Step-by-Step Cleaning Process

Pre-Clean Inspection: Check for excessive mud buildup, oil stains, or trapped debris between tread patterns.

High-Pressure Wash: Use moderate-pressure water jets; avoid corrosive chemicals that can weaken polymer surfaces.

Disinfection (If Required): In regulated zones or sensitive wetlands, use approved biodegradable disinfectants to prevent cross-site contamination.

Drying: Allow panels to air dry completely before stacking to prevent trapped moisture.

Final Review: Ensure that interlocks and bolt holes are free of sediment or residue.

Inspection Routine Before Reuse

Composite mats experience repetitive stress with every deployment. Inspect each panel for visible cracks, delamination, and deformation. Replace or repair panels showing:

Crushed connection ends

Warped surfaces or bent hardware

Reduced traction due to excessive wear

Missing or loose interlock pins

Signs of UV damage or brittleness

Logging inspection results helps track product age and retirement dates, ensuring consistent safety and performance across your fleet.

Storage Guidelines to Maximize Longevity

Storage is more than stacking panels. Proper methods prevent warping, moisture damage, and surface contamination.

Choose Level, Dry Ground: A well-drained surface prevents bottom-layer distortion.

Stack Evenly: Use crossbars or spacers every few layers to distribute weight evenly.

Cover but Ventilate: Shield from UV rays and rain while allowing airflow to prevent trapped heat and condensation.

Rotate Inventory: Use a first-in, first-out system to keep usage balanced across all mats.

Secure the Perimeter: Prevent movement during high winds or transport by strapping the stack carefully.

Environmental and Safety Benefits

Routine maintenance keeps mats structurally sound and environmentally responsible. Clean mats mean less soil transfer, lower runoff pollution, and safer job sites. Proper storage prevents accidental slips caused by moisture or algae buildup.

Partnering for Reliable Service

Reputable mat suppliers can provide professional cleaning and repair services between projects, ensuring each mat remains field-ready. Their technicians inspect joints, traction surfaces, and flex patterns for early signs of fatigue—reducing the chance of mid-project failure.

Industry Perspective

According to the Environmental Protection Agency, uncontrolled sediment transport and cross-site contamination are leading contributors to environmental restoration costs on temporary worksites. Proper cleaning and inspection routines directly reduce those risks while extending usable product life.

Consistent cleaning, inspection, and storage discipline turn composite mats from consumable gear into long-term assets. Routine care ensures every deployment starts safe, stable, and compliant—protecting both your investment and the environment.

How to Design Temporary Access Roads with Composite Mats (Drainage, Crowns, and Curves)

Building a reliable temporary access road requires more than setting composite mats. Each section must support heavy machinery, shed water effectively, and stay stable around bends and inclines. When roads fail, the cost of recovery and downtime far exceeds proper planning.

Understanding Composite Mat Behavior

Composite mats distribute weight evenly while flexing slightly to follow the ground. This balance is key to creating a surface that resists rutting yet adapts to uneven terrain. The design must anticipate how mats interact with underlying soil and how water will flow across or under the mat system.

Road Design Basics

A well-built temporary road starts with the same principles used in permanent construction: stable subgrade, proper drainage, and controlled alignment. The main difference is that composite mats create a reusable, non-invasive surface that can be installed and removed quickly.

Design Steps for Temporary Roads

Survey the Site: Identify low areas, water flow patterns, and soft soils before mat delivery.

Establish a Crown: A gentle crown (2–5%) directs surface water toward the shoulders, preventing ponding.

Plan for Drainage: Use culverts, geotextiles, or under-mat channels where water crosses the path.

Handle Curves Carefully: Increase mat overlap or interlock depth on curves to prevent displacement under turning forces.

Transition Points: Reinforce entry and exit areas where vehicles leave firm ground for softer zones.

Monitor Deflection: Watch for flexing or mat shift under heavy loads, especially during rain or thaw cycles.

Drainage Design in Practice

Drainage failure is the number-one cause of access road degradation. Composite mats perform best when placed over a well-drained surface. Adding geotextile fabric below the mats allows water to pass while retaining soil. Crowns should follow natural topography, never fight it. On slopes, use staggered seams to prevent channeling.

Managing Curves and Elevation Changes

Curves and grades test every mat system. Tight bends concentrate load on the outside edge, which can lead to shear or slip. Extend the mat width by at least one panel in these sections to maintain traction and edge support. For slopes, alternate panel orientation to lock in the structure and reduce creep.

Field Verification Checklist

Before vehicles roll, crews should inspect the route for:

Proper crown height and direction

Intact interlocks across transitions and turns

Clear side drains and culverts

Firm mat seating without bounce or gap

Visual signs of softening or pumping during initial passes

Sustainable Efficiency

Construction mats reduce site disturbance and allow roads to be reused on multiple projects, saving material and labor costs. A trusted supplier will help model soil strength, drainage rates, and mat configurations to fit each project’s terrain and equipment mix.

Supporting Industry Guidelines

Temporary road construction recommendations from the U.S. Army Corps of Engineers emphasize drainage and crown maintenance for all-weather reliability. Following these standards with a modern composite mat system ensures compliance and reduces long-term restoration work.

Temporary roads built with smart drainage, smooth crowns, and well-anchored mats keep jobs running even when the weather turns. A few hours of careful design prevent weeks of rework and repair.

How to Choose Site Mats by Soil Type and Equipment Load

Choosing the right composite mats protects the ground, keeps crews safe, and keeps projects on schedule. Conditions shift from dry sand to sticky clay within a single corridor. Each soil type supports weight differently, so your mat plan must match soil behavior, moisture, and expected axle loads.

Start With the Ground You Have

Confirm the dominant soil type across the access route and work pads. Sandy soils drain fast and shear under turning forces. Clays hold water and pump under repeated loads. Silts behave unpredictably when saturated. In wetlands or tidal areas, bearing capacity changes with weather and season. Map these zones before you set a single panel.

Match Mat Rating to Equipment

Heavy tracked excavators, lattice cranes, and loaded haul trucks demand high-density composite mats with proven interlocks and high bending strength. Medium-duty gear like pickups, UTVs, and light lifts can use thinner profiles that still spread loads. Always cross-check machine weight, ground pressure, and turning radius against the mat data sheet.

Quick Pairing Guide

Dry sand: aggressive tread surfaces that resist lateral shear, medium to heavy-duty panels for turning areas.

Wet sand or silty sand: heavy-duty panels with close interlocks to limit pumping and edge roll.

Firm clay: medium to heavy-duty panels, traction surface to prevent slick starts and stops.

Saturated clay or silt: heavy-duty panels plus thicker pad build, stagger seams under crane outriggers.

Organic or peat soils: continuous coverage with heavy-duty mats, minimize point loads, and avoid sudden turns.

Control Moisture and Deflection

Standing water and thaw cycles reduce support dramatically. Add geotextile separators or a drainage plan where pumping is visible. Watch for deflection near seams. If tires cut, double up panels at haul road entrances, tight corners, and laydown pads. Train spotters to pause traffic when uplift or bridging appears.

Safety and Environmental Gains

Composite panels do not absorb water and clean easily between sites. Crews track less mud onto public roads and reduce cross-site contamination. Ground cover limits rut depth, keeps root systems intact, and protects wetlands during temporary access.

Cost Efficiency That Lasts

Upfront price is only one part of the equation. Reusable panels reduce remediation, towing, and lost hours. Durable interlocks shorten installation and reduce rework when the weather turns. A reliable mat supplier can review route geometry, axle weights, and pad needs to right-size your inventory.

Verify With Trusted References

The USDA NRCS soil resources explain how texture and moisture affect bearing capacity and rutting risk. Use these guides when planning haul roads and pads to reduce failures and restoration costs. See the overview at the NRCS Web Soil Survey (external).

Final Field Check

Before mobilization, walk the route, measure soft spots, and confirm turning radii. Update the mat plan when weather shifts or loads increase. Small adjustments in coverage now prevent big repairs later. The key consideration will be to determine how mats are deployed in view of the current weather and terrain conditions.

A Perspective Look at Pipeline Skids vs Construction Mats

Pipeline projects require dependable ground support, but not all solutions are created equal. Contractors often weigh pipeline skids against construction-grade composite mats when deciding how to stabilize terrain, protect equipment, and meet environmental requirements. Each option brings unique advantages and limitations, and understanding the differences can help you avoid costly missteps in the field.

Performance Under Load

Pipeline skids, usually timber, elevate pipe and allow airflow. They work for short-term stabilization but can degrade quickly with moisture and repeated handling. Construction mats spread loads evenly and stay consistent on wet or uneven ground, making them better for repeated heavy-equipment traffic and haul roads.

Environmental Impact

Because pipeline skids are wood-based, they can rot, absorb chemicals, or carry invasive species from one site to another. Construction mats offer a more controlled profile. Composite mats, in particular, resist absorption and are easier to clean, reducing cross-contamination risks. This difference becomes critical in sensitive areas such as wetlands or agricultural land.

Composite HDPE interlocking mats — best for wetlands corridors, agricultural fields, and soft rights-of-way where fast cleanup and decontamination are required under permits.

Timber/hardwood crane mats — suitable for short-duration, static lifts on firmer upland areas where cost sensitivity outweighs long-term reuse.

Trackout/egress mats — positioned at site exits to reduce sediment transfer, plant material, and contaminants from tracked or wheeled equipment entering public roads.

Cost and Longevity

Upfront, skids are cheaper. But frequent replacement and disposal add up fast. Composite mats typically deliver more service life and can be redeployed across projects, lowering effective cost per use.

Handling and Logistics

Skids are heavy and require more equipment to move, stack, and reposition. Interlocking construction mats are lighter and faster to install, which matters when access must be built and removed multiple times or when weather windows are tight.

Key comparison points

Use this at-a-glance summary as a scoping checklist. Confirm each point against soil conditions, load cases, handling needs, and lifecycle budget before procurement.

Timber skids/mats: lower upfront cost, shorter lifespan, heavier to handle

Composite mats: higher initial cost, longer lifespan, lighter and easier to clean

Use-fit: composites lower environmental risk; timber can fit short, static-load projects

Maintenance & cleanliness: composites are non-porous/easier to sanitize; timber can retain moisture and oils

Which Mat To Use

For temporary elevation alone, skids can be enough. For reliable access, repeat use, and simpler cleanup, construction mats offer better lifecycle value. Explore specifications or request a quote to find out what construction mats can do for you.

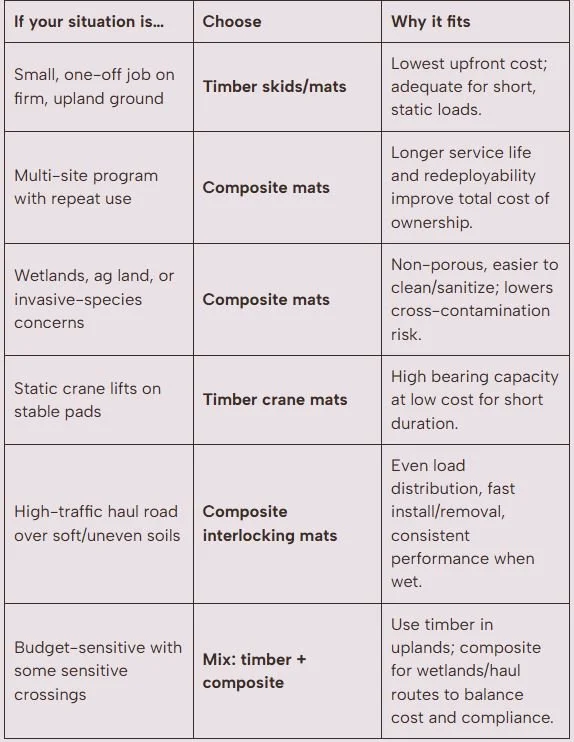

How to Make an Expert Choice Between Timber or Composite Mats

Selecting the right access mats can feel like a tough call. Timber has been the jobsite standard for decades, while technology has pushed composite site mats into the mainstream. Which option makes the most sense for your project? By weighing performance, cost, and environmental impact, you can make confident choices that protect both budgets and worksites.

Key comparison points

Use this at-a-glance summary as a scoping checklist. Confirm each point against soil conditions, load cases, handling needs, and lifecycle budget before procurement.

Timber mats: lower upfront cost, shorter lifespan, heavier to handle

Composite mats: higher initial cost, longer lifespan, lighter and easier to clean

Use-fit: composites lower environmental risk; timber can fit short, static-load projects

Maintenance & cleanliness: composites are non-porous and easier to sanitize; timber can retain moisture and oils, increasing cross-site contamination risk

Compare Durability and Strength

Timber mats are strong but subject to rot, moisture absorption, and cracking—especially with repeated wet/dry cycles. Composite mats (typically HDPE) resist weathering and chemicals and deliver more consistent performance over time. For multi-site programs, that durability can reduce replacements, freight, and downtime.

Evaluate Environmental Impact

Timber can retain oils and moisture and is harder to sanitize between sites, which increases the risk of cross-contamination. Composites are non-porous and easier to clean, supporting SWPPP goals and helping protect sensitive soils and wetlands.

Look at ROI

Upfront, timber appears cheaper. But frequent replacement, heavier freight, and disposal add up quickly. Composites typically last longer and can be redeployed across projects, improving total cost of ownership. If you manage a multi-site portfolio or seasonal programs, lifecycle math often favors composites after the first few turns.

Timber’s weight drives higher handling costs and more equipment moves. Interlocking ground protection mats are lighter and faster to place, which matters on tight timelines or when access must be built and removed multiple times. Faster install/removal also reduces exposure to weather windows.

Mix and Match Mats

Every job is different, and benefits from different mat tyoes. Large transmission or renewables projects benefit from composite longevity and cleanability. Short, static lifts on firm pads may justify timber. Align your choice to load case, soil conditions, environmental constraints, and how often the route will be built, moved, or reused.

Composite Mat FAQ

Q: Are composite mats always the best option?

A: Not always. For small, one-off projects on stable terrain, timber may be more cost-effective. The value of composites grows with repeat use, wet conditions, or environmental sensitivity.

Q: Can timber and composite mats be used together?

A: Yes. Many teams mix: timber under static crane pads; composites for haul roads, wetlands crossings, and high-traffic corridors to reduce rutting and simplify cleanup.

Making the right decision comes down to performance, environment, logistics, and lifecycle cost.. If you need help sizing a route or pad, or want a side-by-side comparison for your next bid, the best course of action is to talk to a construction mat representative. Managing site access without sacrificing environmental concerns is easier than you may think.

5 Best Practices for Swamp Mats on Sensitive Wetlands

Sensitive wetlands present unique challenges for construction projects. Heavy equipment is often necessary, yet these environments can be easily damaged. Using composite site mats allows access while protecting fragile soils and vegetation. The question is, how do you use them correctly? Follow these best practices to safeguard wetlands and keep projects compliant and efficient.

Plan Access Routes Carefully

Before moving equipment, identify the narrowest, firmest crossing points. Favor previously disturbed corridors to avoid new impacts. Schedule work during low-flow or frozen-ground periods to reduce erosion risk. Wetlands make up roughly 5% of the lower-48 land area but support around 31% of U.S. plant species, underscoring the need for careful routing.

Install Composite Mats Correctly

Place swamp mats perpendicular to the travel direction and fit panels tightly. Gaps or rocking can cause shifting and soil washout. Lift mats into place without dragging them to minimize ground disturbance. For heavier loads or high-traffic corridors, interlocking site protection mats improve stability and reduce site restoration. In designated wetlands, protecting the natural environment takes precedence, down to and including using best practices for mat installation.

Limit Equipment Impact

Keep heavy machinery out of wetlands whenever possible. Sensitive terrain is especially susceptible to large pieces of equipment such as trackhoes. Use low-ground-pressure equipment and wide tracks to reduce compaction and maintain natural hydrology. Think “sneakers, not boots”: a smaller ground-contact pressure leaves fewer ruts and preserves water-flow paths that wetlands depend on.

Clean and Remove Mats Responsibly

During and after use, clear mats of soil and plant material. Dispose of debris upland—never into the wetland. Remove mats methodically and restore original grades to speed recovery. For additional wetlands-specific planning guidance, see our post on selecting the ideal matting solution for wetland construction projects.

Restore and Monitor the Site

After removal, stabilize disturbed soils and reseed with native species. Inspect crossings in the following weeks to confirm vegetation regrowth and natural drainage. A documented restoration plan demonstrates environmental responsibility and helps maintain community trust.

Environmental Checklist

Field conditions in wetlands can shift quickly; a structured pre-job review helps protect hydrology, vegetation, and access integrity. Use the checklist below during the pre-job briefing (JSA) and again just before mobilization to confirm matting plans, equipment selection, and restoration measures. Document completion to support permit conditions, safety requirements, and post-project closeout.

Choose minimal-impact crossing points

Install mats tightly and securely

Use low-impact equipment

Clean mats before removal

Reseed and monitor disturbed areas

Protecting wetlands means balancing access with stewardship. By planning routes, installing mats properly, limiting equipment impact, cleaning and removing responsibly, and restoring the site, teams keep projects moving while protecting sensitive ecosystems. It’s good business sense to explore more construction mat solutions.

5 Excellent Uses for Construction Mats After Disasters

Natural disasters leave more than damaged buildings behind. Roads become impassable, soil turns unstable, and recovery crews struggle to move heavy equipment where it’s needed most. Using construction site mats speeds the return of critical services.

Restoring Emergency Access

Floods, hurricanes, and tornadoes often wash out or block local roads. Mats can be deployed quickly to form temporary access lanes for ambulances, fire trucks, and supply vehicles. For routing and traffic flow tips, see our guide on building emergency access roads with mats.

Supporting Utility Repair Crew

Power lines, water systems, and communications infrastructure are frequently damaged during storms. Utility trucks and bucket rigs need firm surfaces to reach broken poles, transformers, and mains. Mats keep vehicles from sinking into saturated soil and help shorten outage durations.

Creating Safe Staging Areas

Recovery requires cranes, excavators, and loaders that impose high ground pressure. Mats form level platforms for equipment staging and lift operations on uneven or muddy terrain. Setting up a stable staging area with site mats allows equipment to be centralized for faster responses. This equates to more efficient restoration of local services, including power and water.

Protecting Sensitive Environments

Many disaster zones border rivers, wetlands, or coastal marshes. Unprotected traffic can degrade these ecosystems and complicate permitting. Routing vehicles over mats limits compaction and rutting while repairs proceed. Explore site-friendly approaches, including wetlands access using composite mats.

Enabling Temporary Shelters and Relief Centers

Displaced residents need safe, dry ground for shelters, clinics, and supply stations. Mats can be laid rapidly to create stable flooring and walkways that remain usable even when the surrounding area stays muddy. Accessible surfaces improve mobility for seniors, children, and medical teams during peak response.

A Field-Use Scenario

After a major coastal storm, response teams established a logistics hub in a flooded fairground. Mats built service lanes for fuel trucks, provided pads for generators, and supported forklifts moving pallets of water and food. What could have taken weeks on saturated soil happened in days because ground support was in place from the start.

Composite Mats Improve Recovery Timelines

Public works priorities concentrate on debris removal, transportation access, water control, public buildings, and utilities. Stabilizing access with mats directly supports these goals by keeping crews moving and heavy assets operating where they’re needed most. When ground support is planned early, restoration phases begin sooner and finish faster.

Rapid Community Benefits

When ground support is planned early, communities start seeing tangible wins within days—not months. The payoffs below show how composite mats speed restoration, improve safety, and protect local environments while keeping recovery work on schedule and within budget.

Faster restoration of transportation and utilities

Fewer secondary impacts to parks, fields, and wetlands

Lowered risk of equipment damage and worker injury

Reusable assets that support multiple incidents over time

They don’t rebuild homes or replace power poles, but construction mats create the conditions that make help possible. By stabilizing ground, protecting natural areas, and enabling safe access, mats help communities recover faster and with fewer setbacks. Learn more on the Select Mat homepage.

How to Choose Between Renting or Buying Composite Mats

Composite mats have become essential for industries that require temporary ground protection. Construction, utilities, energy, and event management all rely on them to create access roads, stabilize heavy equipment, and protect sensitive environments. A key decision for project managers is whether to rent or buy. The right choice depends on project scope, frequency, and budget. Using composite site mats is often the first step toward safer and more efficient projects.

Your Choice Matters

Composite mats represent a significant investment. Renting may appear cheaper at first, but repeated use quickly adds up. Buying provides long-term value, but it also requires storage and upkeep. Wouldn’t you want to know which path protects your bottom line before committing thousands of dollars?

When Renting Makes Sense

Renting is often best for one-time or short-term projects. If you only need mats for a festival, a construction job that lasts a few weeks, or emergency storm response, site mat rental avoids large upfront costs. Rental companies usually handle delivery, installation, and pickup, saving time for crews. Renting also ensures you get newer mats, since suppliers rotate inventory frequently. The flexibility of returning mats after the project is finished appeals to companies.

When Buying is the Better Option

For contractors with frequent projects, ownership offers major savings. Buying eliminates ongoing rental fees and gives you control over availability. Mats can be deployed on multiple sites without waiting on third-party schedules. Over time, this control reduces downtime and improves efficiency. Buying also allows companies to choose specific mat types tailored to their recurring needs, such as extra-thick ground protection mats for heavy tracked equipment. A cost comparison study found that renting a 3×5 mat at $0.20 per square foot per week adds up to roughly $780 over five years, while purchasing the same mat outright costs about $100. This demonstrates how quickly ownership can pay off when mats are used repeatedly.

Practical Considerations

Ownership requires more than just the initial purchase. Storage and cleaning are vital to ensure mats last through repeated use. Neglecting this care shortens their lifespan and reduces resale value. Companies should also factor in transportation costs, since hauling mats requires specialized trucks and trailers. Proper planning ensures ownership delivers the maximum return on investment.

A Prime Example

Consider a contractor specializing in renewable energy installations. Their projects take them across different regions throughout the year. By purchasing composite mats, they save on repeated rental fees and guarantee mats are always available when schedules change. Over five years, the cost savings from ownership outweigh the initial expense, even after accounting for storage and maintenance.

Safety and Compliance

For crane and heavy-lift operations, OSHA requires firm, drained, and graded ground -or the use of supporting materials such as mats that meet the equipment manufacturer’s requirements. Refer to OSHA’s Ground conditions for cranes (29 CFR 1926.1402) when evaluating rental vs. ownership policies and site preparation plans.

Composite mats are versatile tools, but the decision to rent or buy depends on more than cost alone. By weighing project frequency, logistics, and future needs, managers can choose the option that offers the greatest efficiency

4 Ways to Maximize Renewable Energy Access With Composite Mats

Renewable energy projects often take place in challenging locations. Wind farms are built on rural ridges, solar installations spread across uneven fields, and transmission lines cut through wetlands or remote terrain. Moving heavy equipment into these areas can damage soil and delay construction. Using composite site mats provides the stable surfaces needed to expand renewable energy access while protecting the environment.

Create access roads in remote locations

Many renewable energy projects require heavy trucks and cranes to reach isolated sites. Composite mats can be laid quickly to form temporary roads across soft ground. They spread weight evenly, preventing ruts and stuck vehicles. This keeps projects on schedule and reduces costly delays. In rural Texas, for example, mats help contractors bring in turbine blades that stretch more than 200 feet without sinking into farmland. Crews often report significant savings on towing costs and fewer weather-related interruptions when mats are used consistently.

Protect sensitive ecosystems

Solar fields and transmission corridors often pass through wetlands or environmentally fragile areas. Without protection, construction can disrupt water flow, compact soil, and harm plant life. Crews can use composite mats to move machinery without permanent impact. Studies show that temporary matting significantly reduces the need for post-construction soil restoration. Wouldn’t it be smarter to prevent damage than to repair it later? Mats also give regulators confidence that developers are taking environmental compliance seriously, which can speed up permit approvals.

Support heavy equipment for installation

Cranes, pile drivers, and drilling rigs exert enormous ground pressure. Composite mats provide a stable base that distributes weight and reduces the risk of equipment tipping or sinking. This stability allows crews to work more efficiently, even in areas with poor soil conditions. One scenario involves a wind project in Arkansas where mats allowed safe crane operation during rainy weeks, keeping installation on track despite the weather. Workers also noted that mats reduced delays from equipment repairs, since machinery was not bogged down or damaged by uneven ground.

Improve efficiency during maintenance

Renewable energy sites require ongoing upkeep. Construction mats can be redeployed to create quick access paths. This not only protects the land but also reduces operating costs over the lifespan of the project. For solar farms, mats are often used to support service vehicles during panel cleaning or inverter replacement. For wind farms, mats provide quick routes for crane crews handling gearbox swaps, which can otherwise tear up access roads during wet seasons.

According to market research, ~45% of demand for temporary access and ground protection mats comes from construction projects, where muddy or unstable ground can otherwise cause schedule delays. Using composite mats not only protects soil and turf but also helps renewable energy developers avoid downtime, keeping projects on track in challenging terrain.

Composite mats give renewable energy developers the access they need to succeed in remote and sensitive locations. They help protect natural landscapes, keep projects on schedule, and reduce maintenance costs over time. With their durability and adaptability, these mats play an essential role in building a cleaner energy future.

How to Use Site Mats for Festival Grounds Protection

Outdoor festivals bring people together for music, food, and community, but large gatherings also put enormous pressure on the ground. Thousands of feet, heavy stages, and service vehicles can leave turf damaged beyond quick repair. Using composite site mats provides a reliable way to protect festival grounds while ensuring guests and equipment move safely across the area.

Why Protection is Essential

Festival organizers often rent public parks, stadium fields, or rural open spaces. These areas are not designed to withstand the weight of delivery trucks or constant pedestrian traffic. Without ground protection, compacted soil and ruts form quickly. Turf repair after a single weekend event can run into thousands of dollars. Wouldn’t it be better to prevent the damage in the first place?

How Construction Mats Work

Ground protection mats distribute weight across a wider surface. This prevents wheels, tires, and even foot traffic from sinking into soft ground. Mats also provide a stable surface for equipment such as lighting towers, sound rigs, and temporary shelters. Their interlocking design allows them to cover large areas quickly, creating temporary flooring or access roads wherever needed.

A Festival Example

Picture a summer concert in a city park. Semi-trucks deliver stage equipment while food vendors set up nearby. Without mats, the wet soil turns into deep ruts, leaving organizers with costly landscaping bills. By laying site mats in advance, the grounds stay protected, trucks move without sinking, and the park reopens to the public the very next day without visible damage.

Benefits for Festival Management

Site mats provide more than ground protection. They give organizers a tool that simplifies planning and reduces the stress of managing both people and machinery in tight spaces. With mats in place, schedules run more smoothly, equipment deliveries stay on time, and guests feel safer moving through the grounds. They also help avoid last-minute surprises that can delay set-up or force repairs during the event itself.

Reduce slip hazards on muddy surfaces

Protect turf and prevent soil compaction

Support heavy loads from trucks and forklifts

Create accessible paths for guests and staff

Speed up event breakdown and site restoration

Environmental Responsibility

Many festivals now focus on sustainability and minimizing environmental footprints. Site mats align with these goals by reducing long-term harm to the land. Instead of replacing damaged turf or repairing compacted soil, event organizers can return the space in nearly original condition. Protecting natural areas preserves good relationships with communities and makes it easier to secure permits for future events.

Mats come in various types, from lightweight panels for pedestrian areas to heavy-duty composite mats for service roads. Renting may be ideal for one-time events, while larger festivals often purchase mats to reuse season after season. A knowledgeable supplier can advise on which mats best fit the size, soil type, and expected traffic of each event.

How Construction Mats Improve Efficiency in Infrastructure Builds

Infrastructure projects often span large distances and involve challenging terrain, heavy equipment, and tight deadlines. Whether it’s a highway expansion, pipeline installation, or utility upgrade, staying on schedule requires dependable access and minimal disruption. Construction mats play a key role in maintaining momentum by improving ground conditions, reducing delays, and simplifying site logistics.

Establishing Instant Access on Unstable Ground

Many infrastructure projects begin in remote or undeveloped areas with soil that is soft, wet, or uneven. Without ground reinforcement, crews risk delays caused by stuck machinery or impassable work zones. Construction mats create instant, stable platforms that support everything from excavators to delivery trucks. By distributing weight and reducing ground pressure, mats allow operations to begin immediately—even on sites that would otherwise need extensive prep work.

Speeding Up Equipment Movement

Delays in equipment transport can have a ripple effect across an entire job site. Construction mats reduce the time needed to move cranes, trailers, and tracked machines by creating reliable, all-weather pathways. Crews can reposition tools and materials faster, which helps prevent bottlenecks and keep each phase of the project aligned with its schedule. This is especially useful in linear builds like roadways or utility corridors, where progress depends on consistent forward movement.

Reducing the Need for Ground Repair

Heavy equipment can cause ruts, soil displacement, and erosion, all of which lead to additional work and cost. Construction mats help prevent this damage by providing a barrier between machinery and the ground surface. This reduces cleanup and site restoration time, allowing teams to shift focus to the next stage of the build. In areas that require environmental compliance, such as wetlands or protected lands, mats also help projects stay within regulatory guidelines by limiting surface disturbance.

Supporting Reusability Across Project Phases

Infrastructure jobs often move in stages, from clearing to installation to final testing. Construction mats are highly reusable and can be picked up, cleaned, and redeployed as the project progresses. This flexibility eliminates the need to source new materials at each phase and allows project managers to maintain control over equipment access without incurring repeated delivery costs. Mats can even be transferred between multiple jobs, adding long-term value to each investment.

Enhancing Safety for Crews and Equipment

Efficiency is about more than speed—it’s also about preventing accidents that lead to delays. Construction mats are often built with anti-slip surfaces and edge designs that improve traction for both vehicles and workers. This is critical on infrastructure sites where rain, ice, or debris could otherwise create unsafe conditions. By reducing risk, mats help keep operations moving without interruption due to injuries or equipment incidents.

When timelines are tight and terrain is unpredictable, construction mats provide a clear advantage. Their ability to create instant access, protect the site, and support mobility makes them a valuable asset in any large-scale infrastructure build.